Breadcrumb

- Home

- Historical Instruments

- Lundgren Impactor

The Lundgren Rotating-Drum Impactor

Introduced in 1967 by Dale A. Lundgren, the rotating-drum impactor marked a significant advancement in aerosol science. It was among the first instruments designed to measure the time varying nature of airborne particle size distributions, offering valuable insights into atmospheric and workplace exposures.

Its innovative rotating collection surfaces, the outside of a rotating drum, allowed for particles to deposit in sequence during the time of sampling, a week, day, or 8-hr work shift. This design went on to influence many subsequent aerosol samplers, making the Lundgren impactor a foundational tool in exposure sampling.

How the Impactor Works: Precision in Motion

Airborne particles enter the impactor through a carefully controlled flow system, setting the stage for a highly targeted separation process. Inside, the air stream passes through four sequential stages each equipped with a nozzle and a matching collection plate.

As the air accelerates through each stage, particles with enough inertia are flung out of the stream and captured on the plate. Smaller particles, less influenced by inertia, continue on to the next stage. Each level is precisely calibrated to isolate particles within a specific size range, progressing from the largest to the smallest.

This smart design allows for efficient, size-based separation of particulate matter. Once collected, the particles can be analyzed to uncover their composition, concentration, or even their source providing valuable insights for research, health, and environmental monitoring.

Click here to see the original journal article of the Lundgren Rotating Drum Impactor

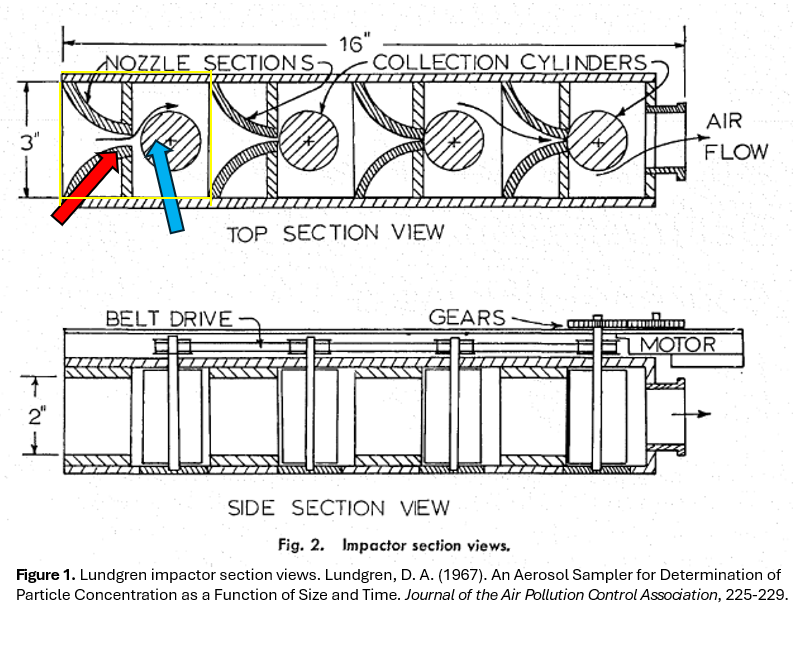

Figure 1 shows a cross section of the Lundgren Rotating-Drum Impactor with arrows pointing to the rotating drum and rectangular nozzle. Each stage of the impactor consists of a rectangular nozzle (red arrow) that accelerates the air and a rotating drum (blue arrow) where particles deposit on its outer surface; the first stage is highlighted with yellow.

After sampling, particle deposits can be gravimetrically or chemically analyzed to determine particle concentration larger than the stage 50% cutoff diameter.

The first stage collects the largest particles, whereas subsequent stages have smaller nozzles that accelerate the air to higher and higher velocities. This enables each stage to collect smaller and smaller particles.

Collection Efficiency of the Lundgren Rotating Drum Impactor

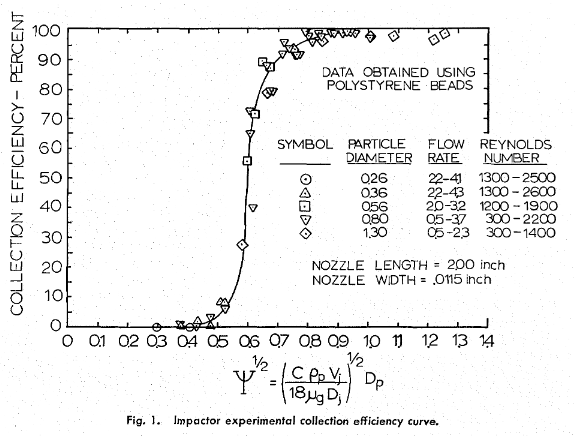

Figure 2: Impactor experimental collection efficiency curve. Lundgren A. Dale (1967). An Aerosol Sampler for Determination of Particle Concentration as a Function of Size and Time. Journal of the Air Pollution Control Association, 225-229.

Figure 2 shows the impactor's experimental collection efficiency curve, with the y axis representing efficiency and the x representing particle diameter. Based on Figure 2 we can tell that this impactor can efficiently collect particles larger than 0.56μm.

The black arrows in Figure 3 represent how air moves through the instrument. Particle laden air is sucked through the air- intake and passes through each of the four stages before exiting the instrument through an after-filter.

prominently featured in Figure 4 are the four collection cylinders, as described in Figure 1(blue arrow). An after-filter (green arrow) which captures ultra-fine particles missed by the four stages. Also visible are key components of the system: a pressure gauge to indicate airflow in the lower left and the central dial that controls the motor speed of the rotating drums.

Applications of the Lundgren Rotating Drum Impactor

- Lundgren rotating drum impactor was used to confirm earlier California Air Resources Board's (ARB) model estimates of health impacts downwind of the Roseville railyard based on diesel exhaust, while adding data on very fine transition metals and contaminated soils, potentially important to human health. Cahill, T. A., Cahill, T. M., Barnes, D. E., Spada, N. J., & Miller, R. (2011). Inorganic and Organic Aerosols Downwind of California’s Roseville Railyard. Aerosol Science and Technology, 45(9), 1049–1059. https://doi.org/10.1080/02786826.2011.580796

Lundgren rotating drum impactor was used during the Los Angeles smog studies, taking aerosol samples every two hours at Cal Tech in Pasadena. These samples were analyzed and the data helped researchers understand the role of gasoline emissions in the formation of smog